TRANS ADRIATIC PIPELINE (TAP) DRAINAGE CHANNEL

CC8TM was used for the protection against further erosion of a drainage channel in Alexandroupolis of Thrace in Greece, as part of the construction of the Trans Adriatic Pipeline (TAP), which will transport Caspian natural gas to Europe.

Sand bags were specified to formed the newly formed channel.

In November 2018, Concrete Canvas® (CC) was used to protect against further erosion of a channel which had been naturally established ditch in Alexandroupolis, Thrace. The lining of this channel with CC was a part of the Trans Adriatic Pipeline (TAP) project which involves the construction of a pipeline to transport natural gas. The pipeline will begin at the border of Turkey and Greece, crossing northern Greece and across the Adriatic Sea via Albania to tie into Italy’s gas transportation network in the South.

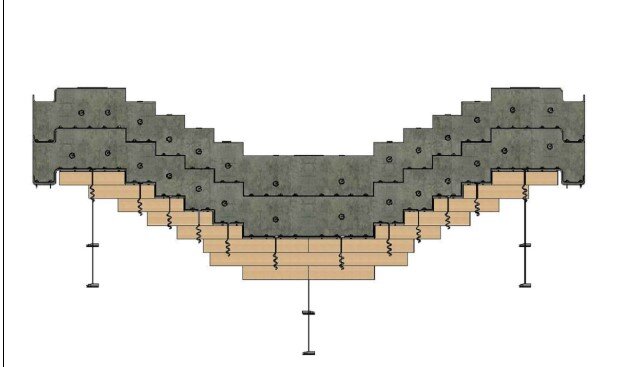

As part of the construction of the Trans Adriatic Pipeline (TAP), an area of 20 meters wide on an existing slope on either side of the pipeline was excavated and cleared. Appropriate dykes and structures were then created to direct the rainwater into an existing natural ditch.

Additional measures to protect the slope were the implantation of grasses in combination with a special biodegradable net so as to retain the seeds of soil and restore the vegetation of the forest area that was harvested. However, the aforementioned works that caused the change in the terrain, combined with the large volume of rainwater and the steep gradient of the slope, resulted in soil erosion both along the slopes and the ditch adjacent to it. 2 Channel Lining Alexandroupolis in Thrace, Greece www.perendes.

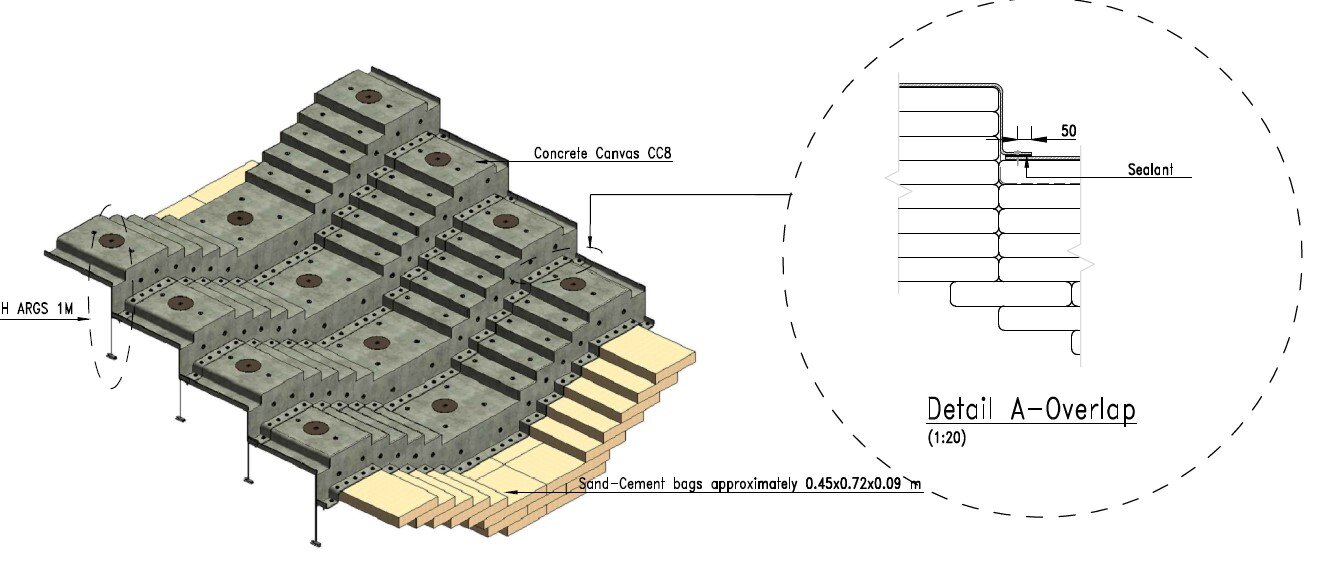

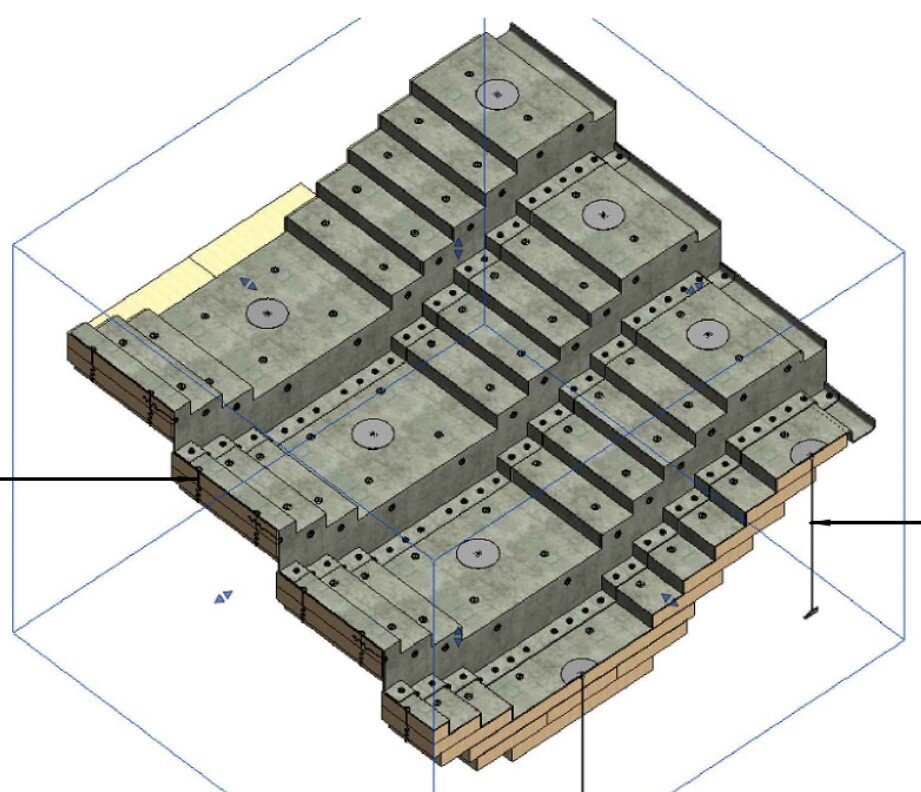

Once the channel had been prepared for installation, the CC was laid transversely across the channel with the work team ensuring an overlap of 100mm between the subsequent layers of the material. The same procedure was followed successively along the entire length of channel.

The edges of the CC material were fixed to the substrate with steel ground pegs which were inserted through each overlap at the shoulder of the channel, within pre-dug anchor trenches which were then back filled to prevent ingress.

All overlaps were sealed with Soudaseal 250XF Foil, an adhesive sealant approved by Concrete Canvas Ltd, to improve joint impermeability, and jointed with 25mm screws at 200mm intervals. It was important to hydrate under the overlap prior to applying the adhesive sealant in order to remove excess dust, ensuring contact with the fibrous top surface of the bottom CC layer and to provide moisture for curing.

A number of options were considered for this project. Initially, a biodegradable erosion mat attached to stones taken from the excavation work was installed to retain the fine-grained soil until vegetation re-established itself on the site. Larger stones were placed in the lower part of the channel to dissipate the velocity of water flow. Overtime, however, the net began to break up and efforts to hold the fine substrate failed. As a result, the stability of the slope was compromised.

Shotcrete was then considered, but due to the heavy forestation within the area, local authorities banned the use of conventional concrete forms.

Another solution was to use sandbags containing sand and cement to create the final channel, with the hope that the sandbags would reduce the water flow. When the creation of the channel was underway, the construction team noticed the fabric containing the sand-cement mixture was not reliable in changeable weather conditions. As a result, a further solution was sought to prolong the life of this channel design

Following each day’s work, the CC was hydrated using water deployed from a hose. The required volume of water required for hydration was decided based on the weather conditions and as per the guidelines of CC’s Hydration Guide.

Works were carried out by the official contractor for the TAP project within Northern Greece, SPIECAPAG, and subcontractor AKTOR, with consulting and design services provided by Perendes Technologies

In preparation for the installation, the existing, naturally formed channel was excavated to create a uniform channel profile and a geomembrane laid. Sandbags were then laid within the channel to ensure a uniform and stable structure, along with creating a stepped design to dissipate water energy. Steel anchors were inserted through the sandbags to join them, while galvanized steel anchors were used to secure them to the substrate

“1325 SQM WERE INSTALLED IN 20 DAYS”

The team of engineers of SPIECAPAG-AKTOR have trusted Concrete Canvas to protect not only the channel but also to improve the overall water drainage system of the wider region. Impressed by the fast and easy installation of the CC, and having ensured the reduced permeability and durability they were looking for, they continued the installation of CC along the rest of the channel. Concrete Canvas is a ideal choice for similar future projects.